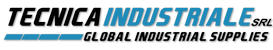

Strength, flexibility, durability and reliability are all vital qualities in the field of power transmission. With Gates Synchronous Belts Poly Chain Carbon Volt, you can be confident that all these are guaranteed. The Gates Poly Chain Carbon Volt belt consists of a tough, lightweight polyurethane compound with carbon tensile cord. The carbon fibre reinforcement provides high strength and length stability with improved shock load and fatigue resistance, while reducing stretch and increasing flexibility. The new facing covering the teeth is a graphite fabric that gives the necessary static-conductivity to the belt.

Construction features

Static conductive to ISO 9563 throughout the lifetime of the belt

Patented static conductive construction

High fatigue-resisting carbon fibre tensile cord

Patented carbon tensile cord design

Suitable for high torque, low speed drives

ATEX directive compliant: suitable for environments with explosive atmospheres

Benefits

Precise drive solutions

Unsurpassed quality

Clean, quiet, compact, durable

Extraordinary power capacity

Supports a maintenance-free, energy saving, environmentally friendly operation

Suitable for temperatures from -54°C to +85°C

Compatible with genuine Gates Poly Chain GT sprockets

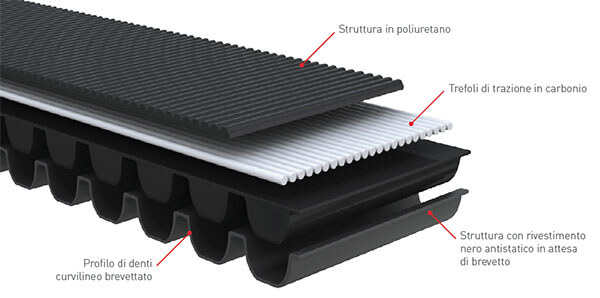

Gates Synchronous Belts Poly Chain GT Carbon

Gates Poly Chain GT Carbon synchronous belts have a renowned industry reputation for high performance and huge cost savings in a range of applications, designed to handle longer center distances at high load-carrying capacities. Gates uses patented Carbon Fiber tensile cords for increased horsepower rating, compactness, and flexibility, while also allowing the use of backside idlers. When combined with Gates Poly Chain GT2 sprockets, you’ll have a lightweight, long-lasting, maintenance-free system that’s more than a match for roller chain.

Our Gates Poly Chain GT Carbon belt drives have immediate impact on your application, with proven success stories, performance and savings metrics from operations all over the world.

Durable polyurethane construction resists chemicals, oil, pollutants, and abrasion.

Fully operational in temperature extremes of -54°C to +85°C (-65°F to +185°F).

High power density with a lightweight, clean-running construction.

FEATURES AND BENEFITS

Our patented, curvilinear tooth profile provides high shear strength, noise reduction, and improved load-carrying capacity.

Equivalent capacity to roller chain drives in the same width.

Easy, rust-free wash-down with Gates Stainless Steel hardware.

Fast drive conversion payback. Quieter than roller chain drives.

Lubrication, re-tensioning and maintenance free.

Gates Synchronous Belts PowerGrip GTX

Gates PowerGrip GTX belts are the newest premium rubber synchronous belts in the Gates belt range. Available in 8M and 14M pitches, this belt is the optimum choice for high-performance, high-torque conditions and quiet operation. Whether it is for a new drive design or for a replacement, you can be confident in PowerGrip GTX reliability.

CONSTRUCTION FEATURES

High-strength, low-elongation tensile cords for extreme shock load resistance

Quiet-running and maintenance-free

Compact, light-weight, economic

Perfect fit on HTD profile pulleys

Anti-static (ISO 9563) as well as REACH and RoHS compliant

Standard available in pitch lengths from 264 mm up to 4578 mm, and in widths of 20, 30, 40, 50, 65, 85 mm (8M) and 20, 40, 55, 85, 115, 170 mm (14M). Other dimensions available on request

On demand available in PowerPainT construction, to eliminate paint contamination risk

BENEFITS

Easy replacement of existing HTD/GT3 type applications, reducing the overall drive package while at the same time increasing the power capacity by 40% over PowerGrip GT3

Reliable operation and trouble-free service, extending the useful life of your system

Substantial reduction of your day-to-day operational costs by eliminating downtime and maximising productivity

Gates Synchronous Belts Poly Chain GT2

Gates Poly Chain GT2 has been designed for optimum performance also on high torque, low speed drives in any industrial application. This lightweight belt features increased power ratings of up to 40% higher than previous constructions (Poly Chain GT), while maintaining the same long service life. Gates Poly Chain GT2 operates on Poly Chain GT pulleys. Its construction is based on innovative state-of-the-art design.

The body and teeth of the belt are made of a unique polyurethane compound, making the belt tough and virtually immune to abrasion and chemical attack. Poly Chain GT2 belts make an excellent alternative to roller chains, requiring neither re-tensioning nor lubrication. Space-saving, weight-saving and money-saving, Gates Poly Chain GT2 drives offer a long and reliable service life.

Identification

Three part number on the back of the belt indicating pitch code, pitch length and width.

Construction

Teeth and body are made of a lightweight polyurethane compound, specially blended for adhesion to the cords and fabric. This uniquely formulated polyurethane makes the belt tough and virtually immune to abrasion and chemicals.

The aramid tensile cords provide extraordinary power-carrying capacity.

Flex fatigue life of aramid is exceptional, and its high impact strength withstands shocks and surge loading.

The fabric covering the teeth is highly resistant to oil, chemicals, pollutants, corrosion and abrasion. It is exceptionally durable and remains fully operational under extreme temperatures from -54°C up to +85°C.

The fabric facing reduces friction with the pulley, thereby minimising temperature build-up.

Advantages

Substantially increased power rating.

High efficiency positive drive.

Maintenance-free: no lubrication or re-tensioning needed.

Savings in space, weight and money

Gates Synchronous Belts PowerGrip MXL

The Gates PowerGrip MXL belt is a classical synchronous belt with a pitch of 0.08” (2.032 mm). It is recommended for applications where maximum synchronisation, small package and high speed are required. Space-saving and highly stable, this belt is the ideal solution to precision drives such as office machines and computers.

Identification

Three part number on the back of the belt indicating pitch length, tooth pitch and belt width in code.

Construction

• Trapezoidal tooth form.

• Elastomeric backing and teeth combine durability and light weight.

• Nylon facing protects and reinforces the tooth surfaces.

• Fibreglass cords provide length stability and flexibility.

Advantages

• Power transmission of up to 0.8 kW and speeds of up to 20,000 rpm.

• Gates PowerGrip MXL belts allow small pulley diameters (from 6 mm diameter) with a maximum number of teeth in mesh.

• Highly suitable for stepper motors.

• Accurate positioning.

• Very stable.

Gates Synchronous Belts Twin Power

Due to its double and directly opposite teeth, Gates Twin Power synchronous belts ensure high loading capacity on contra-rotating drives and ensure smooth running and high flexibility. They are available with the classical trapezoidal tooth profile and also with the unique GT tooth profile. A Twin Power GT2 belt has twice the power rating of a Twin Power HTD belt. It is characterised by extraordinary load-carrying power and high tooth jump resistance ensuring a positive non-slip drive. In addition, the belt runs at very low noise. Gates Twin Power is available in PowerGrip GT2 8MGT and 14MGT, HTD 5M and PowerGrip XL, L And H pitches.

CONSTRUCTION

Similar in construction to PowerGrip classical synchronous and PowerGrip GT2 belts: strong fibre glass tensile member precisionformed elastomeric teeth and body.

Wear resistant nylon fabric on both tooth sides.

Standard widths per belt pitch in mm and belt width code:

Twin Power PowerGrip GT2

8MGT: 20, 30, 50, 85 mm

14MGT: 40, 55, 85, 115, 170 mm

Twin Power PowerGrip HTD

5M: 9, 15, 25 mm

Twin Power PowerGrip:

XL:

6.4 mm (code 025), 7.9 mm (code 031),

9.5 mm (code 037)

L:

12.7 mm (code 050), 19.1 mm (code 075),

25.4 mm (code 100)

H:

19.1 mm (code 075), 25.4 mm (code 100),

38.1 mm (code 150), 50.8 mm (code 200),

76.2 mm (code 300)

BENEFITS

High loading capacity.

Twin Power can transmit up to 100% of its maximum rated load from either side of the belt; alternatively, it can transmit a load on both sides – provided the sum of the loads does not exceed the maximum capacity.

Non-slip positive drive.

Running at low noise.

Free of lubrication and maintenance.

Temperature range: -30°C to + 100°C.