Motor and drive technologies setting new standards worldwide

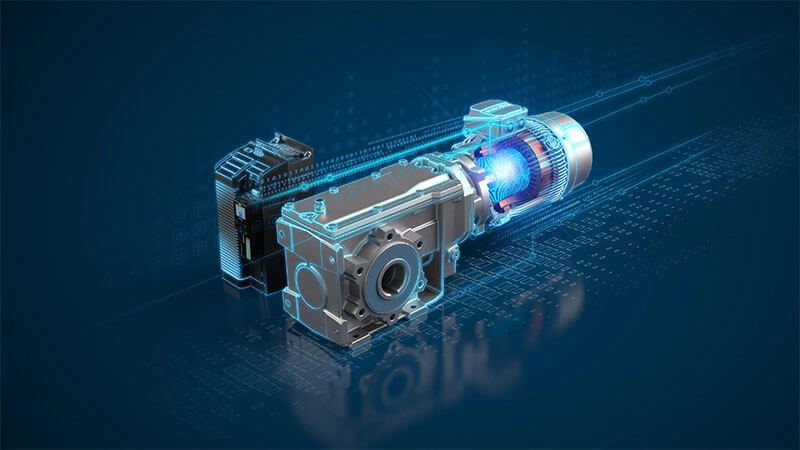

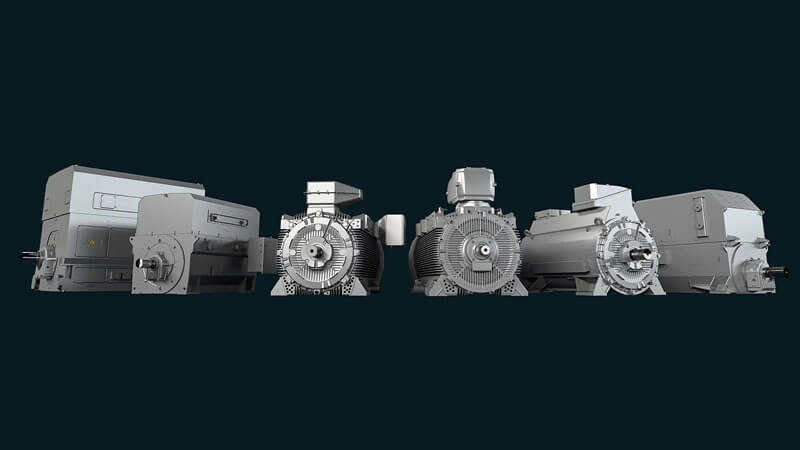

The proven reliability, uninterrupted service, and over 150 years of engineering excellence have secured Innomotics’ drive technologies top positions in customer confidence. Innomotics’ lineup of motors, generators, converters, motor spindles, geared motors, and drive systems is robust, eco-friendly, adaptable, and flexible. Experience the fusion of extensive engineering knowledge and forefront innovation in electrical solutions that powers our offerings.

Redefining power and motion for industrial applications

Innomotics’ forward-thinking range of motors, drives, systems, services, and solutions supports the vital industries at the very heart of entire economies. Innomotics serves almost all industries, from chemicals, oil & gas to utilities, from fiber to automotive and marine, from water to waste water. Customers trust Innomotics’ portfolio for industrial applications to help them scale up efficiency, electrification, sustainability, and digitalization while reducing their carbon footprint.

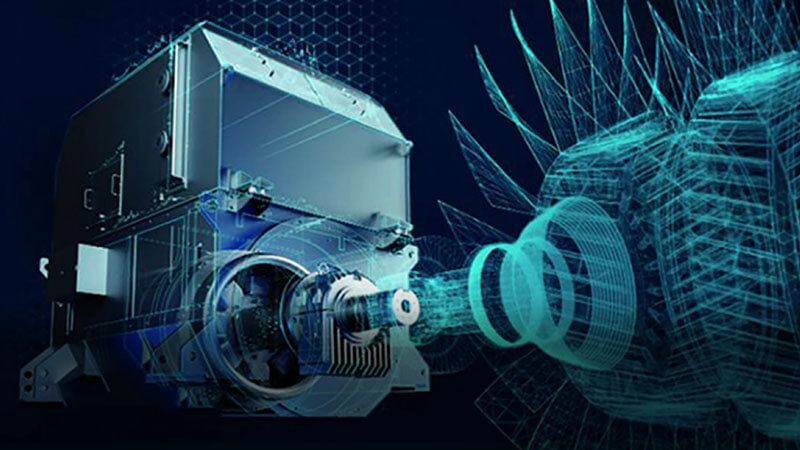

TURBINE REPLACEMENT

As global carbon tax laws emerge, energy companies are increasingly exploring ways to diminish their plant’s carbon footprint. Electrification stands out as a pivotal strategy. Transitioning to electric drive technology for rotating equipment in Oil & Gas, petroleum, and chemical refinery applications offers a seamless pathway, eliminating the reliance on high-carbon fuels.

Innomotics’ electric drive train systems provide up to 6 years of uninterrupted operation. This includes high-speed motors like the SIMOTICS HV Series HS-modyn and advanced VFD (Variable Frequency Drive) technology. These systems boast unparalleled onboard redundancy options, ensuring maximum reliability in operation.

TEST APPLICATIONS

Innomotics offers testing equipment that meets the most exacting standards of design and technology. Whether for research and development, quality assurance, or insurance purposes, our systems adeptly handle even the most intricate tasks with unwavering reliability.

Automotive manufacturers and their suppliers achieve excellence through rigorous research, development, and meeting stringent quality standards. This demands test equipment solutions capable of realistically simulating the full spectrum of mechanical loads experienced by vehicles and components. These solutions must also enable swift recording and analysis of measured values to ensure comprehensive evaluation.

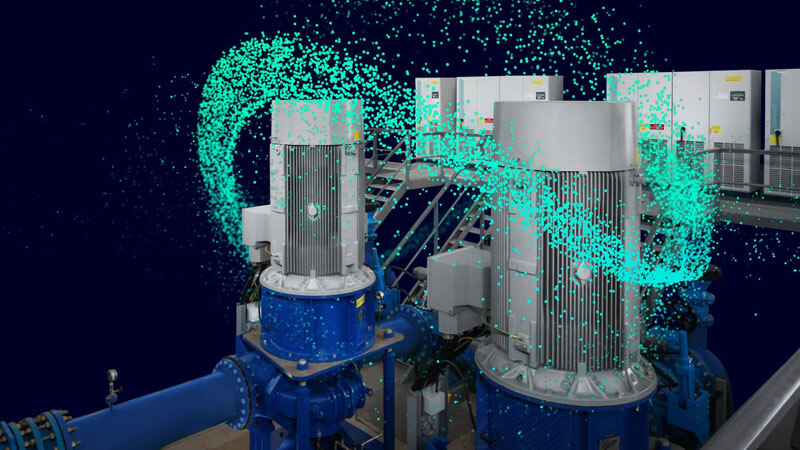

PUMPS, FANS AND COMPRESSORS

Machine builders and plant operating companies across process industries and infrastructure sectors benefit significantly from the dynamic synergy of SIMOTICS & SINAMICS.

The SIMOTICS & SINAMICS systems, designed specifically for pumps, fans, and compressor applications, are intricately aligned for seamless operation. The windings and rated currents of SIMOTICS motors are precisely harmonized with the voltages, currents, and pulse patterns of SINAMICS variable frequency drives. This meticulous matching elevates system efficiencies and availability, facilitating a customized dimensioning that further enhances overall system efficiency.