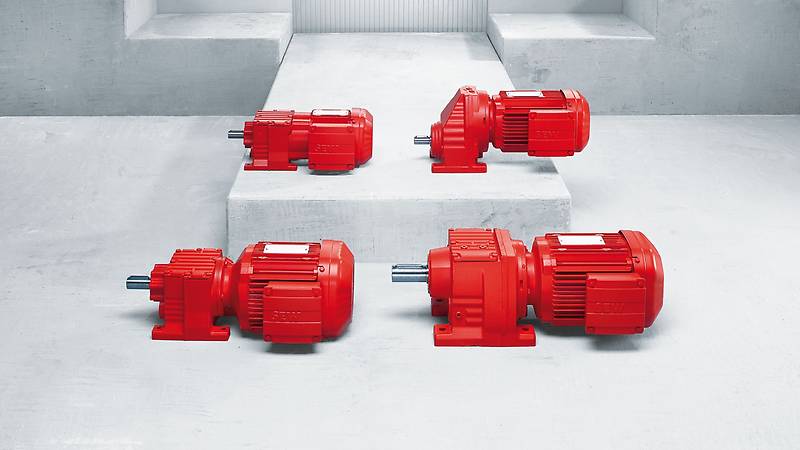

With our Sew Eurodrive standard gearmotors, helical, helical-bevel, parallel-shaft, helical-worm and SPIROPLAN gearmotors we offer a unique range in the industry. The world is our gearmotors’ area of application. The world of motion.

R..DR.. series Sew Eurodrive helical gearmotors

Make use of the advantages of the compact combination of powerful helical gear units and AC motors. Our Sew Eurodrive helical gearmotors of the series R..DR.. set themselves apart with their finely stepped gear unit ratios and variety.

Energy-efficient: individually configurable helical gear unit with motor

Our Sew Eurodrive helical gearmotors of the series R..DR.. are universal all-rounders for many of your application areas. With their high efficiency, they are ideally suited for a multitude of applications.

Thanks to our consistent modular system, the helical gearmotors of the series R..DR.. offer you many combination options.

Regardless of the helical gearmotor design you finally decide on: You are always getting an optimum ratio between performance and intelligent use of space. Especially when you are looking for a space-saving drive solution.

Even at the level of energy efficiency, the Sew Eurodrive standard gearmotors of the series R..DR… offer you excellent product characteristics. This is particularly true for the AC asynchronous motors of the sophisticated efficiency classes IE3 and IE4.

Make use of this high energy efficiency in your applications. The helical gearmotors of the series R..DR…come in either a foot or flange-mounted design making a range of assembly options possible.

F..DR.. series Sew Eurodrive parallel-shaft gearmotors

The parallel-shaft gearmotors of the series F..DR.. are perfect for all your design-related applications where you rely on space-saving components. They provide optimum installation conditions thanks to their slim design.

High-torque drive: Sew Eurodrive Parallel-shaft helical gear unit and performance-optimized AC motor

Space-optimized drive solutions are sought by you specifically in conveyor and process engineering. This is because your system architecture often only offers limited space for drive technology.

We offer you our parallel-shaft gearmotors of the series F..DR… for these applications. Use this structural advantage and benefit from the remarkably slim design of our parallel-shaft gearmotors F..DR…

Thanks to our modular concept, which allows for combining gear units and motors as needed, we can easily meet individual and application-specific requirements and in this way implement optimal solutions for you.

A high degree of flexibility is offered to you by the parallel-shaft gearmotors of the series F..DR.. and by the solid or hollow shaft design options in this series. Our entire spectrum of AC asynchronous motors is available to you when selecting the motor.

In this way, you combine space-saving design with force, dynamics and reliability for a powerful parallel-shaft gearmotor.

K..DR.. series Sew Eurodrive helical-bevel gearmotors

Our Sew Eurodrive helical-bevel gearmotors K..DR.. are an excellent choice for many applications that require compact drives with high efficiency. As they are especially low-maintenance they will reduce your costs in day-to-day operation.

Helical-bevel gearmotors: low-maintenance and high efficiency

Are you looking for a low-maintenance and largely wear-free but high torque drive solution? Then you are making the right decision with our helical-bevel gearmotors K..DR.. This is because we offer you gear units and motors combined as compact drive components: perfectly in tune with each other and adapted to your application.

Due to their design, our helical-bevel gear units are especially robust and low-maintenance. The reason for this is the high-endurance gearing and the high manufacturing quality of all component parts. Combine this helical-bevel gear unit with an AC motor and you get a powerful and compact helical-bevel gearmotor: with high efficiency and, depending on the energy efficiency class required, with a motor power range of up to 200 kW.

Irrespective of the application you wish to implement, the combination options for helical-bevel gear units K..DR.. are diverse: wide range of gear unit ratios, foot or flange-mounted design for flexible installation and motor variants for energy efficiency classes IE1 to IE4.

S..DR.. series Sew Eurodrive helical-worm gearmotors

Due to their design and from being combined with a helical gear stage, Sew Eurodrive helical-worm gearmotors S..DR.. have particularly high efficiency. They are also extremely low-noise and thus avoid high noise emission levels.

Low-noise continuous operation: gear unit combination optimized with respect to efficiency

Do you expect a drive solution to impress you with its high level of performance and efficiency? In that case, we would recommend our high-quality helical-worm gearmotors S..DR.. to you. These can be implemented individually in the modular system. In this way, they offer you an enormous range of sizes, gear ratios and motor sizes.

However, their greatest strength is their running smoothness and their extremely low noise development. One thing is certain – With the helical-worm gearmotors S..DR.. you are choosing a powerful drive solution which you will hardly even hear.

The overall concept also offers you many more practical product characteristics and benefits.

These include the significantly higher efficiency of the helical-worm combinations as opposed to single helical-worm gear units. This is how you save additional energy in the operation of your systems and are able to noticeably reduce ongoing operating costs.

You will receive the low-noise helical-worm gearmotors S..DR.. – to suit your individual requirements – with a wide range of AC motors. In addition, you can freely configure all of the relevant properties. In this way, you can effectively make use of all the benefits offered by this combination of low-noise helical-worm gear unit and performance-optimized motor. Even greater variance can be achieved thanks to the optional flange or foot-mounted design and by choosing between solid and hollow shaft.

W..DR.. series SPIROPLAN right-angle gearmotors

Are you looking for drives which bring top speed to your handling application? In that case, the SPIROPLAN right-angle gearmotors W..DR.. are a good choice. Their aluminum housing makes them lightweight; their design makes them space-saving.

Lightweights: the right-angle gearmotors W..DR.. require little space

If your system architecture requires a drive solution that implements top speed, we would recommend our SPIROPLAN right-angle gearmotors: space-saving and simple to install.

The special, wear-free SPIROPLAN gearing offers you a largely vibration-free drive with low weight and high efficiency. Excellent smooth running properties are achieved as a result of this gearing and steel on steel combination of the tooth elements.

The SPIROPLAN right-angle gear units are also maintenance-free thanks to their practical lubrication for life and help you to reduce the ongoing operating costs of your system.

They are real lightweights thanks to their aluminum housing, with which you can of course implement any mounting position you wish.

Be it with hollow shaft or solid shaft, we offer a diverse range of mounting and extension options and motor combinations according to your individual requirement profile. The SPIROPLAN right-angle gearmotors meet the requirements for energy efficiency classes IE1 to IE4 so that you can use them anywhere in the world.